Alpine Dryers Blog

Why Fire Stations Can't Afford Wet Gear

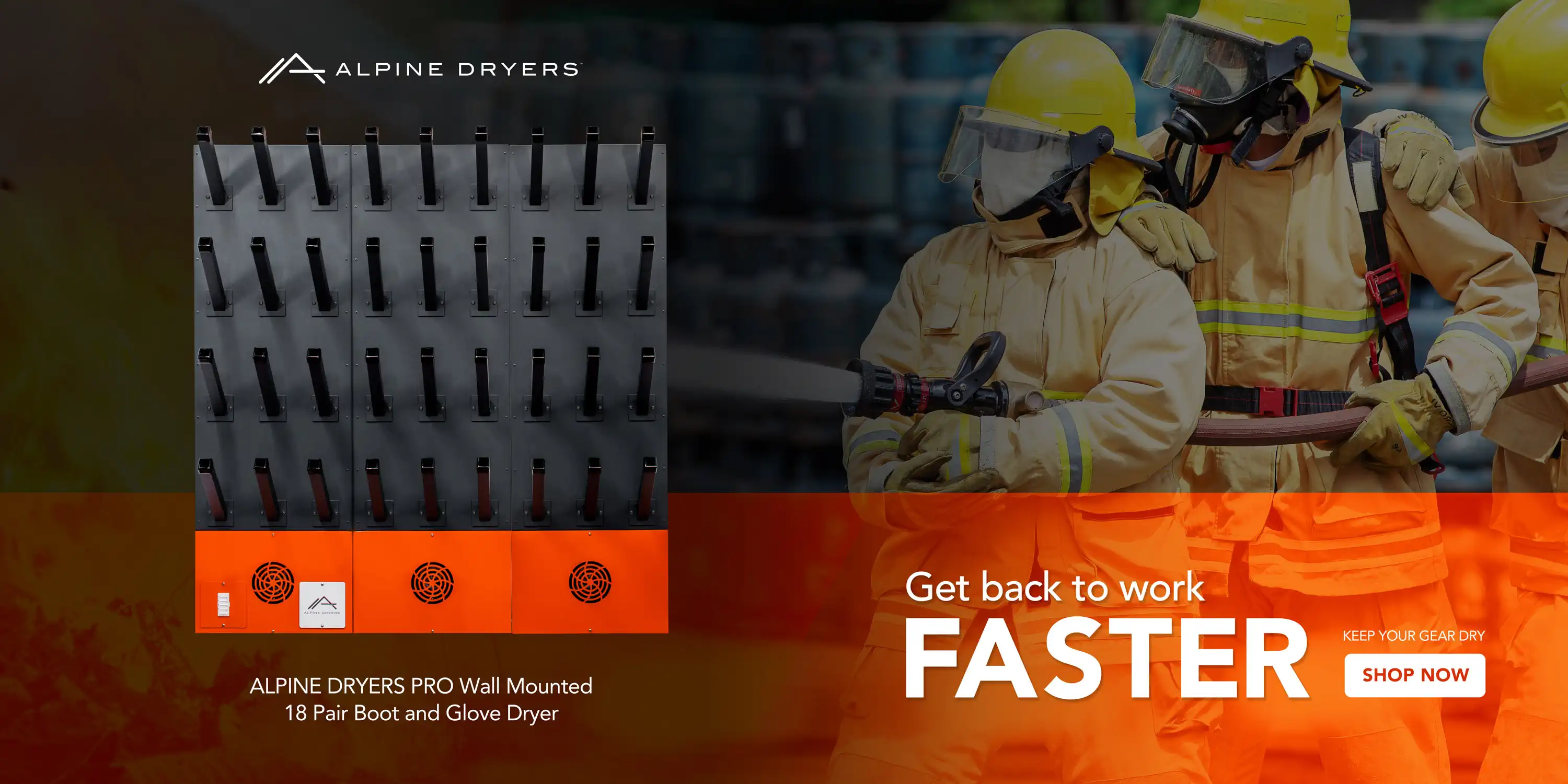

Fire Station Gear Drying: Why Locker Dryers Are Critical

by Alpine Dryers • November 04, 2025

A structure fire at 2 AM. Crews work for three hours in full turnout gear. Everything gets soaked. Water from hoses, water from the building, sweat from the work. The gear comes back to the station dripping.

By 6 AM, there's another call. Same crew, different emergency. The gear from the night shift is still hanging in the bay, still wet. Nobody's getting into dry equipment this time.

This isn't a hypothetical. This is Tuesday at most fire stations. Gear gets wet on calls. The next call happens before things dry naturally. Crews end up working in damp equipment because there's no alternative.

The Safety Problem

Wet gear behaves differently than dry gear. The thermal protection drops. Moisture conducts heat better than dry material. A firefighter in wet turnout gear faces higher burn risk than one in dry gear. This is measurable and well-documented.

Wet boots present their own issues. Less traction. More blistering. Feet get cold faster, which affects performance and decision-making. When you're working a fire scene in winter, cold wet feet become a legitimate problem within minutes.

The equipment standards address this. NFPA guidelines discuss gear inspection and maintenance. Departments are supposed to ensure turnout gear is clean, properly maintained, and ready for use. But "ready for use" implies dry, and most stations don't have effective drying capability.

How Stations Currently Handle It

Walk through a fire station after a working fire. Gear is hanging in the bay on racks. Coats on one side, pants on the other. Boots lined up below. Everything's dripping onto the floor. Fans might be running. Maybe a space heater if it's winter.

This is the standard approach. Air dry whatever you can, hope it's ready for the next call, and deal with it if it's not. Crews get used to putting on damp gear. It becomes normal.

Some stations rotate gear so wet equipment can dry longer between uses. This works if you have spare sets. Most departments don't have that budget. One set per firefighter is standard. Maybe a backup set if funding allows.

Larger departments with more resources sometimes have dedicated gear drying rooms. These work better than bay drying but still rely on ambient air circulation. Without active drying systems, gear needs hours to dry properly. Time fire stations don't always have between calls.

What Wet Gear Costs

Turnout gear is expensive. A complete set runs $3000-5000 depending on specifications. Departments need to outfit every firefighter. The costs add up fast.

Gear that stays wet breaks down faster. Moisture degrades the thermal layers. Seams fail sooner. The outer shell material deteriorates. What should last 10 years might need replacing after 6 or 7.

Calculate this across a department. If wet conditions reduce gear life by 30%, you're replacing equipment years ahead of schedule. For a department with 20 firefighters, that's replacing 6-7 sets early. At $4000 per set, that's $24,000-28,000 in accelerated replacement costs.

Boots face similar issues. The constant wet-dry cycles break down materials. Sole separation happens sooner. Inner lining compresses and fails. Steel toes corrode faster. Boots rated for years of use might last half that under constant moisture exposure.

Built-In Drying Makes Sense

Some fire stations have installed locker dryers integrated directly into their gear storage areas. Not standalone units that dry a few items. Comprehensive systems where every firefighter's locker includes drying capability.

This changes how the station operates. Gear comes back from a call, gets inspected and cleaned per protocol, then goes into lockers with active drying. By the next shift or the next call, it's actually dry. Completely dry. Ready to provide proper thermal protection.

The systems run automatically. No one needs to remember to turn them on or monitor drying times. They operate continuously at safe temperatures that won't damage gear. Strong enough airflow to dry thick turnout material and heavy boots.

For fire stations, this is safety equipment. It belongs in the same category as extraction fans, decontamination areas, and properly maintained apparatus. Things that directly affect firefighter safety and operational readiness.

The Operational Reality

Fire departments operate on tight budgets. Every purchase needs justification. Equipment requests compete with training costs, vehicle maintenance, and staffing needs.

Locker dryers get evaluated against other priorities. Is this essential or nice to have? The answer depends on how you frame it. As a convenience upgrade, it's hard to justify. As safety equipment that extends gear life and maintains thermal protection, the case becomes stronger.

The gear life extension alone can justify the investment. If proper drying adds even two years to turnout gear lifespan, calculate what that saves over time. For a 20-person department, extending gear life from 7 years to 9 years saves roughly $40,000 over that period. The locker dryer installation pays for itself in extended equipment life.

The safety argument matters more but is harder to quantify. How do you value maintained thermal protection? What's it worth to ensure firefighters aren't going into structures with compromised gear because it's still wet from the last call?

Installation Considerations

Fire stations have specific constraints. Space is often limited. Locker areas need to accommodate gear, personal equipment, uniforms, and everything else firefighters store on shift.

Alpine locker systems can be engineered to fit existing station layouts. The modularity matters because every station has different dimensions and different numbers of personnel. A small volunteer department needs a different setup than a 50-person urban station.

Power requirements are straightforward. Most stations have adequate electrical capacity. The systems run on standard power without requiring major upgrades. They're designed for continuous operation, which matches how fire stations actually function.

Durability is non-negotiable. Fire station equipment gets used hard. Lockers get slammed. Gear gets thrown in after calls. The drying systems need to handle this environment without constant maintenance or breakdowns.

Beyond Turnout Gear

Firefighters deal with other wet equipment. Gloves get soaked on water calls. Hood liners are drenched with sweat. Some departments have specialized equipment for hazmat, rescue, or water operations. All of it needs to dry properly.

Wildland firefighters face this even more acutely. Days working fires in remote areas. Limited equipment changes. Everything gets wet from fire suppression, sweat, or weather. The gear needs to be ready for the next operational period, which might be just hours away.

Locker dryer systems can be configured for different equipment types. Boots get dedicated ports. Gloves have drying capability. Turnout gear hangs in ways that maximize airflow. The system addresses everything firefighters wear, not just select items.

The Bigger Picture

Fire departments compete for recruitment. Stations that provide better working conditions attract better candidates. Details matter. A station with proper gear drying shows attention to firefighter welfare and equipment maintenance.

Current firefighters notice these things too. When your department invests in proper drying capability, it sends a message about priorities. Equipment is maintained properly. Safety is taken seriously. The small details that affect daily operations get addressed.

This matters for retention and morale. Firefighters working in stations that properly care for equipment report higher job satisfaction. This is true across industries, but especially relevant for public safety where equipment directly affects worker safety.

Making the Case

For chiefs and fire boards evaluating this investment, the calculation includes multiple factors. Equipment life extension provides measurable return. Maintained thermal protection improves safety in quantifiable ways. Reduced complaints about wet gear improves morale.

The installation serves the department for years. Unlike turnout gear that needs replacement every decade, a properly installed locker dryer system functions for 20+ years with minimal maintenance. The initial investment spreads across a long service life.

For departments applying for grants or seeking funding, this falls into equipment categories that typically get approved. It's not administrative overhead or questionable luxury. It's equipment maintenance and firefighter safety infrastructure.

The question isn't whether fire stations need proper gear drying. The question is when departments prioritize addressing this known issue. Some stations still operate without adequate drying capability. Others have made it standard infrastructure. The difference shows in equipment longevity, operational readiness, and firefighter feedback.